Top Suppliers Liquid Drying - Molecular Sieves – Gascheme

Top Suppliers Liquid Drying - Molecular Sieves – Gascheme Detail:

| Applications | Material | Size (mm) | Shape | |

| 3A(GC-328) | Drying of natural gas and hydrocarbon streams | Zeolite | 1.6~2.5 | S |

| 3A(GC-335) | Drying of natural gas and hydrocarbon streams | Zeolite | 3~5 | S |

| 3A(GC-341) | Drying of cracked gas and hydrocarbon streams | Zeolite | 1.6 and 3.0 | E |

| 4A(GC-412) | Drying of solvents | Zeolite | 0.5~1.0 | S |

| 4A(GC-428) | Drying of natural gas and hydrocarbon streams | Zeolite | 1.6~2.5 | S |

| 4A(GC-437) | Drying of air, natural gas and hydrocarbon streams | Zeolite | 4~6 | S |

| 4A(GC-441) | Drying of natural gas | Zeolite | 1.6 and 3.0 | E |

| 5A(GC-528) | Natural gas sweetening, Purifying of H2 | Zeolite | 1.6~2.5 | S |

| 5A(GC-528C) | Removal of H2S and light mercaptans from Natural gas, CO/.CO2 from H2, N2/O2 seperation | Zeolite | 1.6 and 3.0 | E |

| 5A(GC-532) | Separation i/n paraffins | Zeolite | 2~3 | S |

| 5A(GC-532A) | Natural gas sweetening | Zeolite | 3~5 | S |

| 13X(GC-928) | Drying and sweetening of natural gas andLPG streams, air purifying | Zeolite | 1.6~2.5 | S |

| 13X(GC-935) | Drying and sweetening of natural gas, air purifying | Zeolite | 3~5 | S |

| 13X(GC-938) | Drying and sweetening of natural gas, air purifying | Zeolite | 4~6 | S |

| 13X(GC-941) | Drying and sweetening of natural gas andLPG streams, air purifying | Zeolite | 1.6 and 3.0 | E |

| 13X-HP | Seperation i/n paraffins, PSA O2 | Zeolite | 1.6~2.5 | S |

| XH-5 | Refrigerant R600a,R290,R12,R123,R124,R125 | Zeolite | 1.6~2.5 | S |

| XH-7 | Refrigerant R290,R12,R123,R124,R125,R134a | Zeolite | 1.6~2.5 | S |

| XH-9 | Refrigerant R123,R124,R125,R134a,R143a,R152a | Zeolite | 1.6~2.5 | S |

Remark

Shape: S-sphere E-cylindrical extrudate

Form: 1-Oxide

Our molecular sieves can satisfy your applications for Cryogenic air separation units (ASUs) are built to provide nitrogen or oxygen and often co-produce argon, natural gas dehydration and sweetening, hydrogen purifying in PSA processing, medical & industrial oxygen in PSA/VPSA processing, air braking system. dehydration of hydrocarbon gas or liquid (No Olefins Present), dehydration of hydrocarbon gas or liquid (With Olefins Present), isomerization processes, Feedstock Purification, LPG Desulfurization,

n/i-Paraffin separation, butane destenching, MTBE / TAME, reformer applications, FCC off gas dehydration.

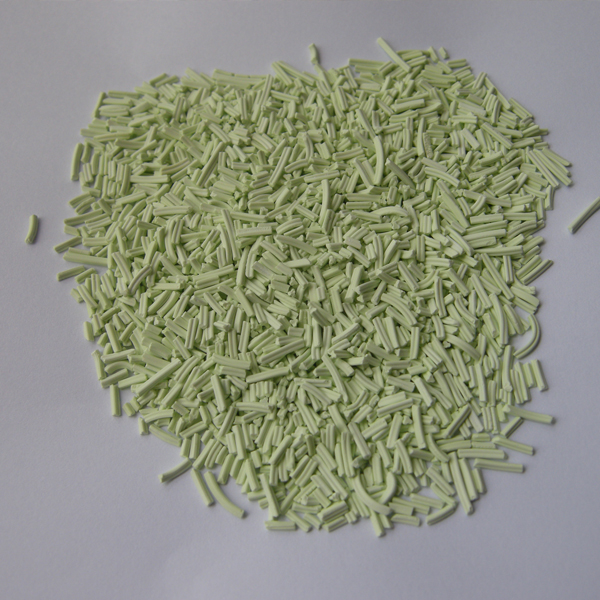

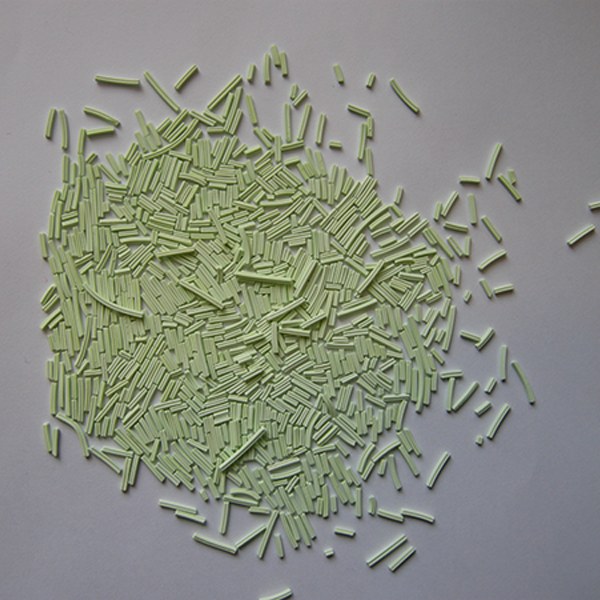

Product detail pictures:

Related Product Guide:

We're committed to furnishing easy,time-saving and money-saving one-stop purchasing support of consumer for Top Suppliers Liquid Drying - Molecular Sieves – Gascheme , The product will supply to all over the world, such as: United Arab Emirates, Mombasa, Cape Town, Strong infrastructure is the need of any organization. We are backed with a robust infrastructural facility that enables us to manufacture, store, quality check and dispatch our products worldwide. To maintain smooth work flow, we have sectioned our infrastructure into a number of departments. All these departments are functional with latest tools, modernized machines and equipment. Owing to which, we are able to accomplish voluminous production without compromising upon the quality.

The sales person is professional and responsible, warm and polite, we had a pleasant conversation and no language barriers on communication.

Write your message here and send it to us